Take you to understand the valve production process

Release time : 2023-11-23Author : XINCHANGJIN MACHINERYRead : 3004times

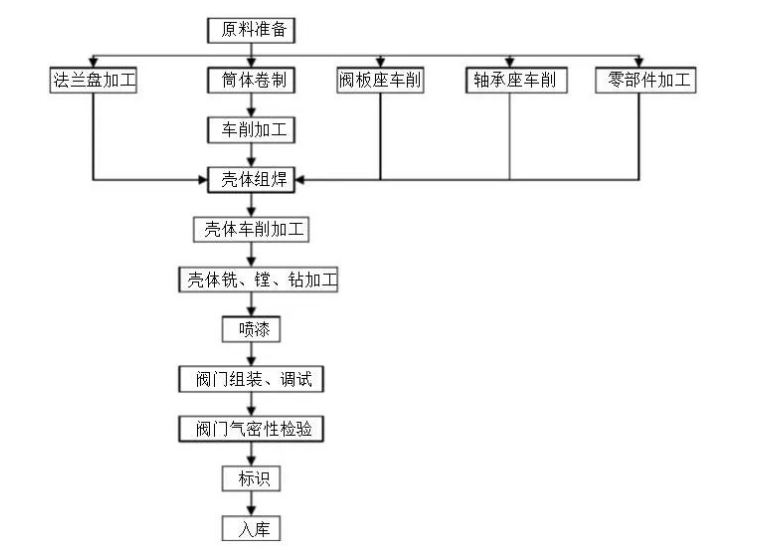

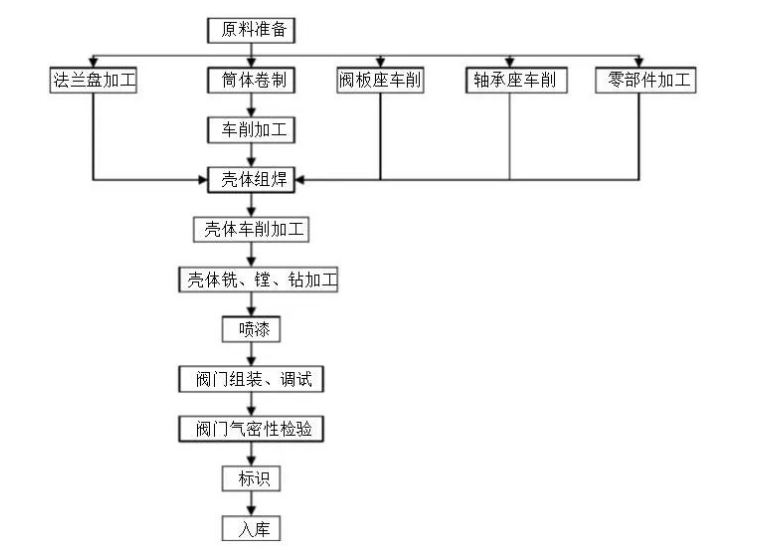

The main components of valve products are valve body, valve cover, bracket, gland, handwheel (castings or forgings are outsourced procurement.) Valve stem, copper nut, bearing, standard parts, seals and other accessories. The company mainly purchases semi-finished products in machining centers, CNC lathes, lathes, washing machines, boring machines, planers, drilling machines and other kinds of machines for finishing. Assemble and sell finished products. Materials are stainless steel, cast steel, cast iron and other materials.

1. Valve body

Valve body (casting, sealing surface surfacing) casting procurement (according to the standard) -- incoming inspection (according to the standard) -- surfacing groove -- ultrasonic detection (according to the pattern) -- surfacing and post-welding heat treatment -- finishing -- grinding sealing surface -- sealing surface hardness inspection, coloring detection.

2, valve internal parts manufacturing process

A, need to surfacing the sealing surface of the internal parts such as valve disc, seat and other raw materials procurement (according to the standard) - factory inspection (according to the standard) - production of blanks (round steel or forging, According to the technical requirements of drawings) -- rough processing ultrasonic flaw detection surface (when the pattern is required) -- rough surfacing groove -- surfacing welding and post-welding heat treatment -- finishing parts -- grinding sealing surface -- sealing surface hardness inspection, coloring flaw detection.

B, valve stem raw material procurement (according to standard) - factory inspection (according to standard) - production of blanks (round steel or forgings, According to the technical requirements of the drawings) -- rough surfacing groove -- surfacing welding and post-welding heat treatment -- finishing all parts -- grinding round -- valve stem surface treatment (nitriding, quenching, chemical coating) -- final treatment (polishing, grinding, etc.) -- grinding sealing surface -- sealing surface hardness inspection, coloring detection.

C, do not need to surfacing sealing surface of the internal parts and other raw materials procurement (according to the standard) - factory inspection (according to the standard) - production of rough (round steel or forging, according to the drawing process requirements) - rough processing of ultrasonic inspection surface (when the design requirements) - finishing each part.

3. Fasteners

Fastener manufacturing standard DL439-1991.

Raw material procurement (according to the standard) - incoming inspection (according to the standard) - production of blanks (round steel or forgings, according to the drawing process requirements) and sampling for the necessary inspection - roughing - finishing - spectrum inspection.

4. Final assembly

Receive parts - cleaning, cleaning - rough assembly (according to the drawing) - hydraulic test (according to the drawing, process) - qualified, disassembled, wiped - final assembly - and electrical or actuator debugging (for electric valves) - paint packaging - shipping.