Comparison and Performance Analysis of Wire Rope Electric Hoists (Type N) in China, Japan, and South Korea

Release time : 2025-03-29Author : XINCHANGJIN MACHINERYRead : 1531times

Comparison and Performance Analysis of

Wire Rope Electric Hoists (Type N) in China, Japan, and South Korea

Electric hoists, as core components of

lifting equipment, rely heavily on mechanical design to determine performance,

safety, and maintenance efficiency. This article compares the structural and

technical specifications of N-type wire rope electric hoists from China, Japan,

and South Korea, focusing on core components, braking systems, reduction

mechanisms, and innovative designs.

I. Comparison of Main Frame and Core

Components

-

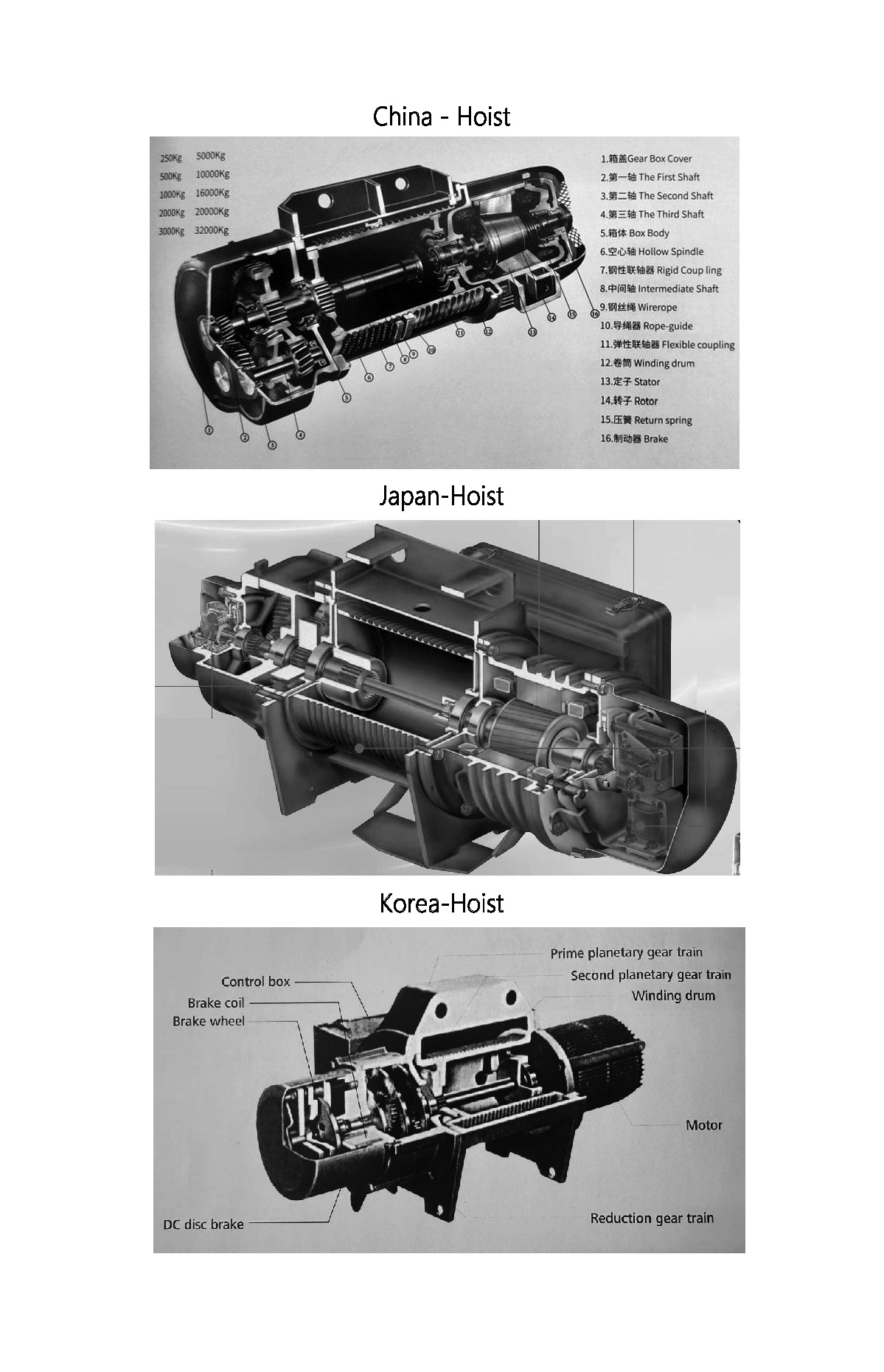

South Korean Electric Hoist

-

Structural Features:

-

The

main frame assembly (MAIN BODY Assembly) integrates a planetary gear

reducer, multi-stage DC electromagnetic brake, and a three-phase

asynchronous motor, with independent installation of components.

-

Planetary Gear Reducer: Utilizes a two-stage planetary gear

transmission (including 1st/2nd internal gears and planet gear cages)

for high transmission efficiency and load distribution.

-

Motor Gear Shaft: Directly connected to the brake, shortening

the power transfer path.

-

Advantages: Modular design simplifies repairs; planetary gears

offer strong impact resistance and stable torque output.

-

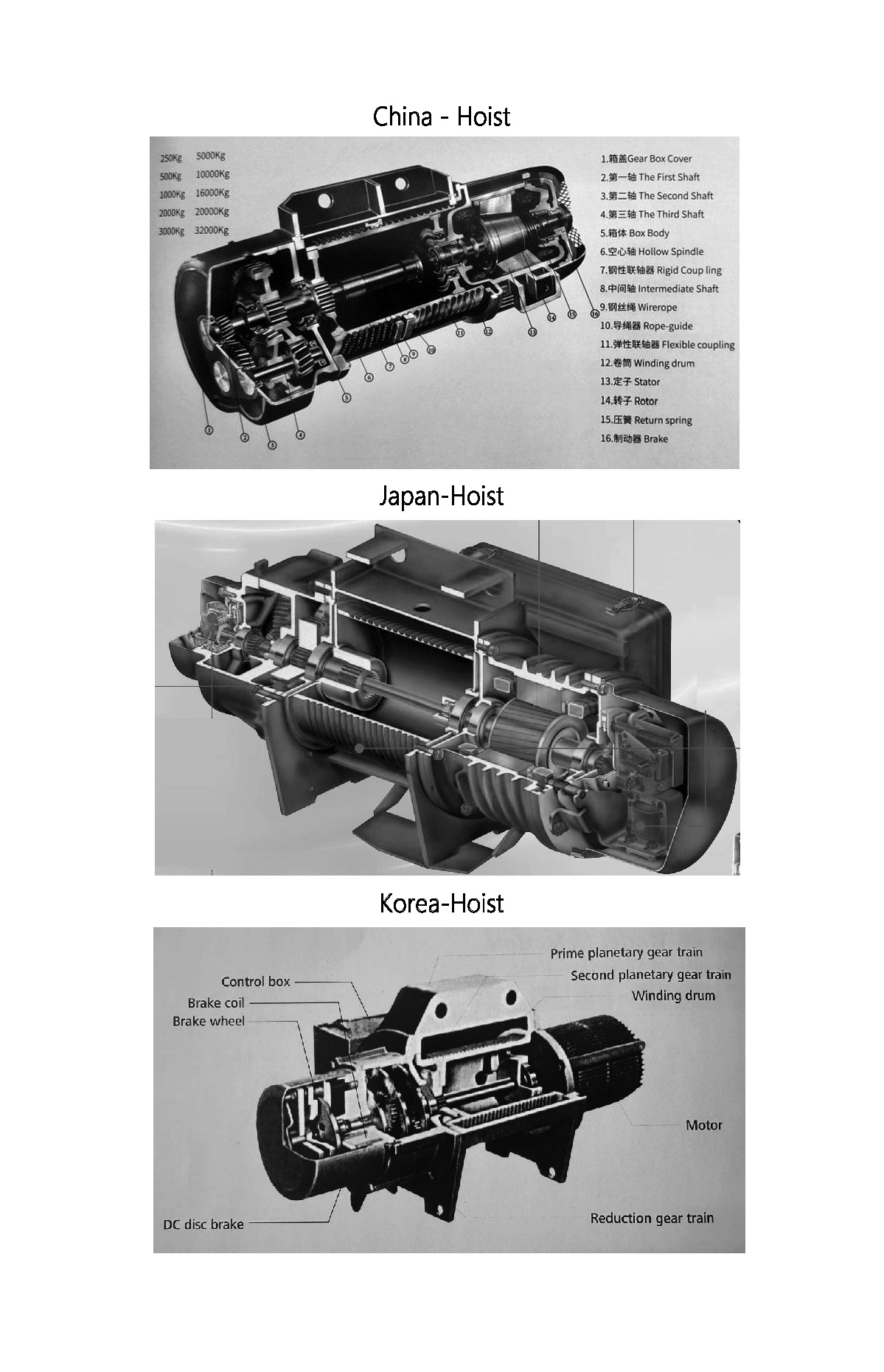

Chinese Electric Hoist

-

Structural Features:

-

The main structure includes a conical rotor motor,

three-stage helical gear reducer, flexible coupling, and cast iron/steel

tube winding drum.

-

Reducer: Employs three-stage helical gears, with the input

shaft connected to the motor via a flexible coupling and the output

shaft (hollow shaft) driving the drum.

-

Braking System: Relies on the axial magnetic pull of the

conical rotor and spring linkage, with the brake wheel coaxial to the

motor.

-

Advantages: Clear power transmission path and low

manufacturing cost; conical rotor ensures rapid braking response and high

safety.

-

Japanese Electric Hoist

-

Structural Features:

-

Integrates an electromagnetic brake lifting motor with a

multi-stage gearbox, featuring an independent brake unit.

-

Innovations: Auxiliary brake unit (redundant braking), new

steel drum and sheave mechanisms, user-friendly pushbuttons, and

integrated cables.

-

Advantages: Rapid technological iteration with human-machine

interaction focus; auxiliary braking enhances safety, and modularity

simplifies inspection.

II. Key Performance Comparisons

-

Braking System

-

South Korea: Multi-stage DC electromagnetic brake (4 friction

plates), independent of the motor and gearbox, ensures direct braking

response and superior heat dissipation.

-

China: Conical rotor magnetic pull braking with spring reset

requires periodic adjustment for wear (axial displacement up to 3–5 mm).

-

Japan: Dual protection via primary electromagnetic brake +

auxiliary braking unit; automatic wear compensation reduces maintenance

frequency.

-

Reduction Mechanism

-

South Korea: Two-stage planetary gears offer compact size,

over 95% transmission efficiency, and outstanding impact resistance.

-

China: Traditional three-stage helical gears ensure mature

technology and low maintenance costs; rolling bearings minimize friction

losses.

-

Japan: Multi-stage gearbox (possibly combining planetary and

parallel shafts) balances efficiency and load adaptability with optimized

noise control.

-

Motor and Power Transmission

-

South Korea: Three-phase asynchronous motor transfers power

via a middle shaft to the planetary gearbox, ensuring smooth torque

output.

-

China: Conical rotor motor enables direct braking via axial

magnetic pull, offering quick start-stop but higher energy consumption.

-

Japan: Integrated electromagnetic brake lifting motor reduces

power loss and improves control precision.

III. Innovative Designs and Application

Scenarios

-

South Korea:

-

Highlights: Modular design, multi-stage brake heat

dissipation.

-

Applications: High-frequency lifting operations, heavy

industries (e.g., ports, steel plants).

-

China:

-

Highlights: Cost-effective conical rotor braking, robust

three-stage gears.

-

Applications: Small-to-medium workshops, construction sites

(cost-sensitive environments).

-

Japan:

-

Highlights: Redundant auxiliary braking, user-friendly

interfaces, lightweight steel drum.

-

Applications: Precision manufacturing, logistics warehouses

(high safety and usability requirements).

IV. Conclusion

-

South Korea: Excels in high-intensity, high-load scenarios with

planetary gears and independent brakes, though maintenance costs are

higher.

-

China: Prioritizes affordability via conical rotor braking and

traditional gears, but requires frequent brake adjustments.

-

Japan: Leads in safety and user experience through redundant

braking and ergonomic design, albeit at a premium price.

Future

trends may integrate modularization (South Korea), intelligent features (Japan’s

auxiliary braking), and cost optimization (China’s helical gears), driving

electric hoists toward higher efficiency, durability, and user-centric

innovation.