Formerly known as Qingdao Changjin Machinery Parts Co., Ltd., Qingdao Xinchangjin Machinery Co., Ltd. was founded in 2008 with a specialty business in machinery manufacturing. Not only Focusing on R&D and manufacturing of Crane Hoist Part, valve accessories, reducers, and other mechanical products, but it is also a modern enterprise combining R&D, manufacturing, foreign trade, marketing, and other services. With high technology as the support, high quality as the core, and innovation as the footing, the company aims to not only provide its customers with the best machinery products but also offer coordinated services from casting and forging non-ferrous metal raw materials to fabricating finished parts and components, along with integrated machining solutions.

The company has a rich supply chain system to provide customers with one-stop service and overall mechanical processing solutions from raw materials to finished parts.

Crane Hoist Part - Wire Rope Hoist- Load Block Ass'y- Brake Part- Reducer Ass'y- Motor Ass'y- Main Body Ass'y- Traversing Trolley Ass'y- Geard Motors- Hook- Sheave- CONTROL BOX ASS'Y- Load Sheave- Other parts

Crane Hoist Part

Crane Hoist PartValve Part - Actuator Valve Parts- Body,Bonnet- Screw Jacks- Hand wheel- Other parts- Stem, Stem Clamp

Valve Part

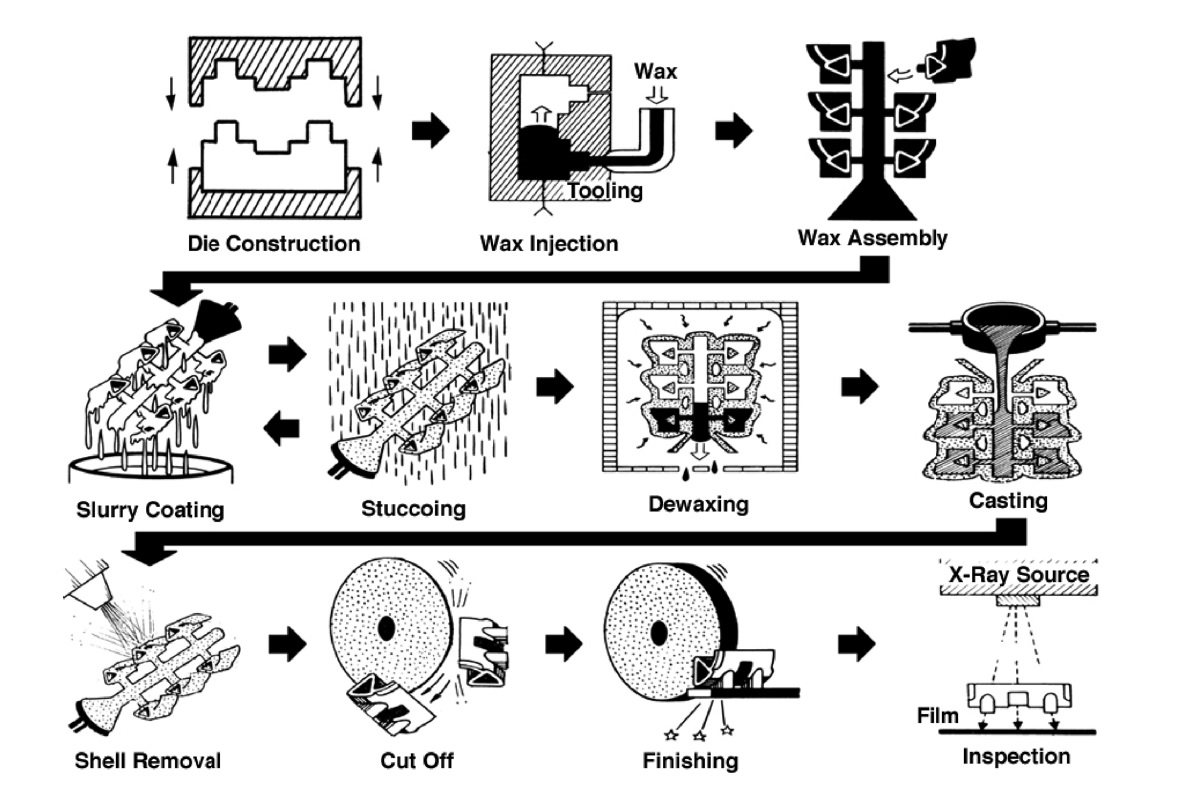

Valve PartCasting / Forging - Investment casting- Sand casting- Powder Metallurgy- Die forging

Casting / Forging

Casting / Forging Mechanical parts

Mechanical parts

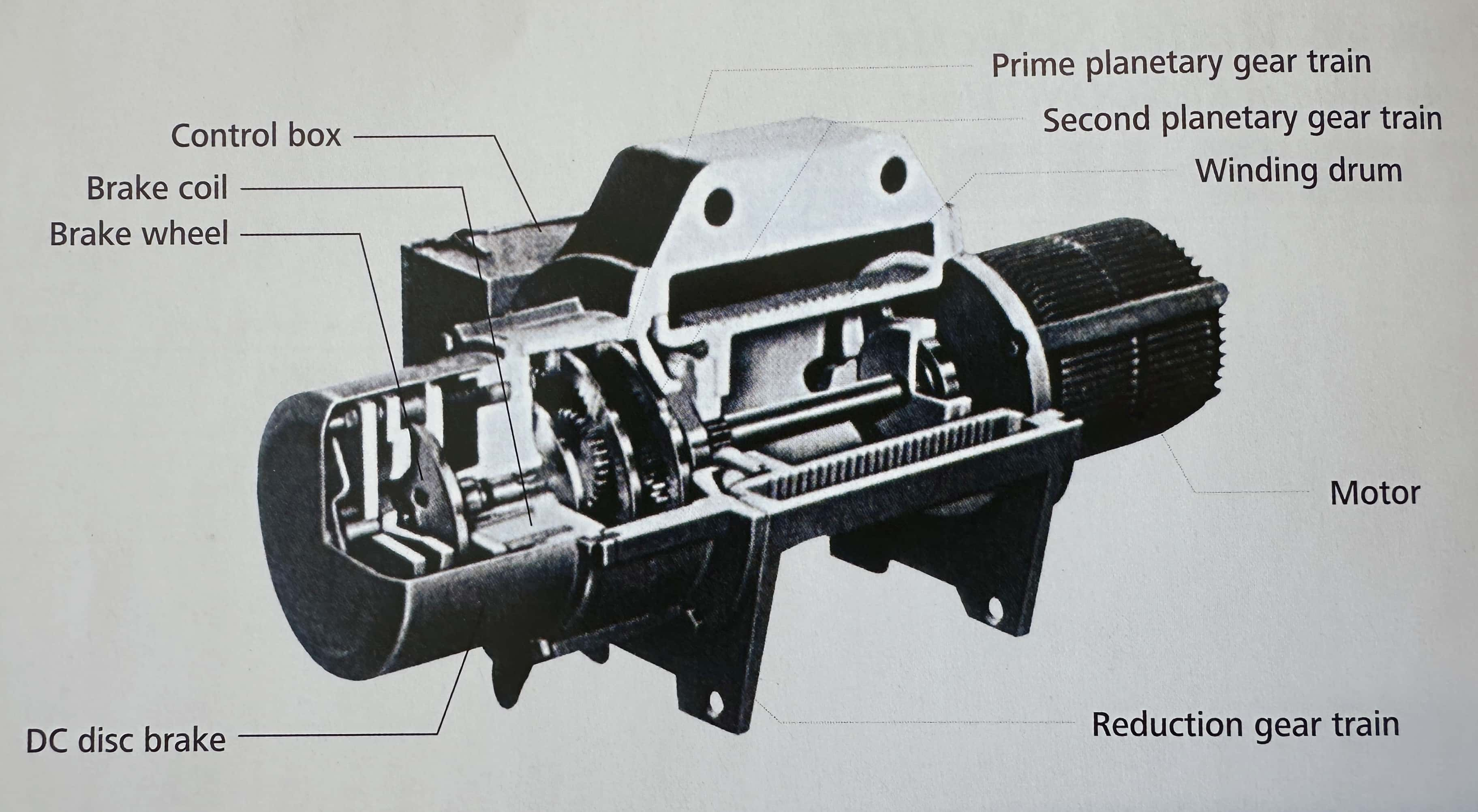

Electric hoists, as core components of lifting equipment, rely heavily on mechanical design to determine performance, safety, and maintenance efficiency. This article compares the structural and technical specifications of N-type wire rope electric hoists from China, Japan, and South Korea, focusing on core components, braking systems, reduction mechanisms, and innovative designs.

Ductile iron, a high-strength cast iron material developed in the 1950s, has now become an indispensable high-quality choice in multiple industrial fields. Its comprehensive performance is close to steel, and it is widely used in casting parts that require complex forces, high strength, toughness, and wear resistance. Today, let's dive deep into the chemical composition, physical properties of ductile iron, and its applications in various fields. Chemical Composition and Unique Properties The

In the field of industrial control, valve pneumatic film actuators play a crucial role. It is not only a key component in automation systems, but also widely used in chemical, water treatment, energy and other industries. Today, we will delve into the internal structure of this device, so that you can understand its working principle and construction in one minute.

Parts are composed of a number of surfaces, each surface has a certain size and mutual position requirements. The relative position requirements between the surface of the part include two aspects: the distance between the surface dimensional accuracy and relative position accuracy (such as coaxiality, parallelism, verticality and circular runout, etc.) requirements. The study of the relative position relationship between the surface of the part is inseparable from the benchmark, without a clear

The main components of valve products are valve body, valve cover, bracket, gland, handwheel (castings or forgings are outsourced procurement.) Valve stem, copper nut, bearing, standard parts, seals and other accessories. The company mainly purchases semi-finished products in machining centers, CNC lathes, lathes, washing machines, boring machines, planers, drilling machines and other kinds of machines for finishing. Assemble and sell finished products. Materials are stainless steel, cast steel,

Mechanical processing refers to the process of changing the overall size or performance of a workpiece through a mechanical device. In the production process, the process of changing the shape, size, position, and nature of the production object to become a finished or semi-finished product is called a process. It is the main part of the production process. The process can also be divided into casting, forging, stamping, welding, mechanical processing, assembly and other processes. The mechanica

The enterprise has always followed the enterprise tenet of "providing customers with valuable products and creating an excellent leading brand in the industry", and established a comprehensive service system for high-quality products with a professional attitude. As the main body of professional machinery manufacturing, technical excellence and innovation, team standardization and cooperation, skill improvement and management, timely and efficient service, form the core competitiveness of the market and industry, and obtain excellent reputation from customers.